Product Description :

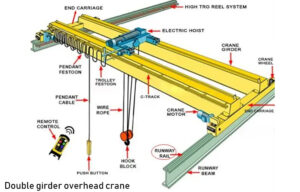

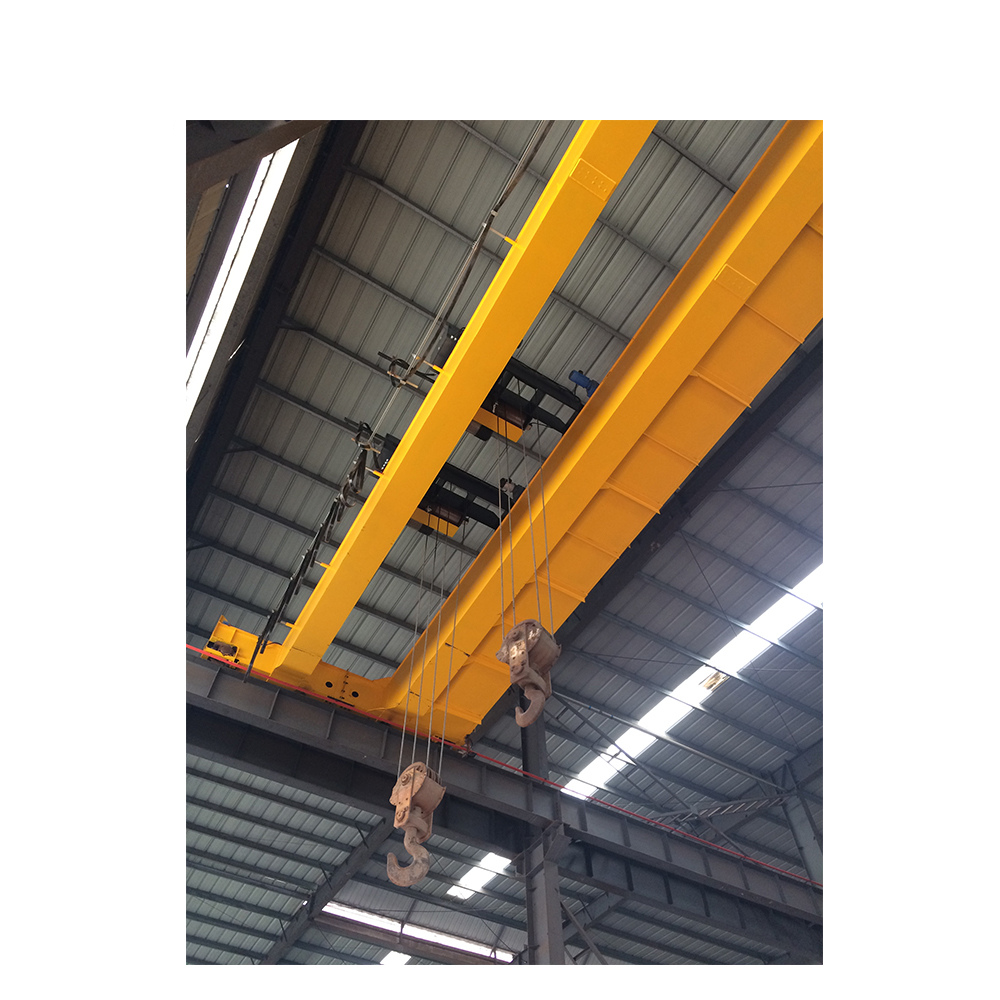

Bridge (Girder):

The bridge is the main horizontal beam that spans the width of the working area. It is supported by end trucks on either side and can move along the length of the crane runway.

End Trucks:

End trucks are located on both ends of the bridge and house the wheels on which the crane travels along the runway beams. The wheels allow the crane to move horizontally, covering the entire length of the runway.

Runway Beams:

Runway beams are the horizontal beams that support the entire overhead crane system. They are typically mounted to the building structure and provide a path for the crane to travel.

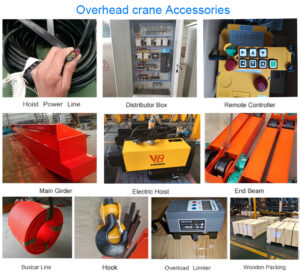

Hoist and Trolley:

The hoist is the lifting mechanism that is attached to a trolley. The trolley moves horizontally along the length of the bridge, allowing the crane to position the load precisely.

Hoisting Mechanism:

The hoisting mechanism is responsible for lifting and lowering the load. It can be an electric or manual winch system, and it is mounted on the trolley. The hoisting mechanism is controlled by an operator to perform lifting and lowering operations.

Control System:

Overhead cranes are equipped with a control system that allows operators to manage the crane’s movement and lifting operations. This can include pendant controls, radio remote controls, or more advanced automated control systems.

Capacity and Span:

Overhead cranes come in various capacities, ranging from small systems for light loads to large cranes capable of lifting several tons. The span, or the distance between the runway rails, can also vary based on the specific application.

Applications:

Overhead cranes are used for a wide range of material handling tasks, including lifting and moving heavy machinery, construction materials, and other large loads within a specified area. They are particularly useful for tasks that require precise positioning and efficient lifting.

Safety Features:

Overhead cranes are equipped with safety features such as limit switches, overload protection, emergency stop buttons, and safety brakes to ensure safe and reliable operation.

Types of Overhead Cranes:

There are different types of overhead cranes, including single girder cranes, double girder cranes, gantry cranes, and jib cranes. The choice of the crane type depends on factors such as the load capacity, span, and specific application requirements.

Reviews

There are no reviews yet.