Maximize Your Warehouse Capacity

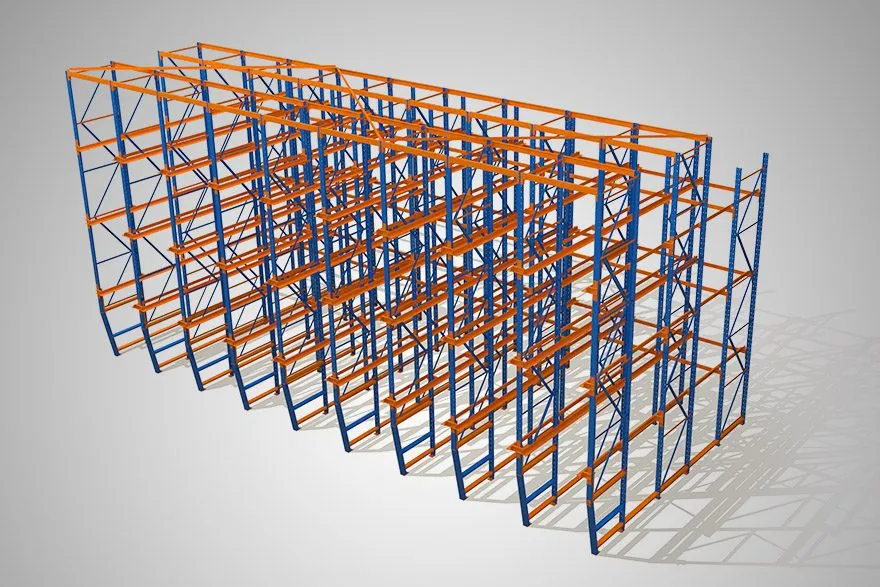

Drive-In Pallet Racks

Additional Services

PERMITS

FIRE INSTALLTION

INSTALLATION

PERMITS

Growing? Add Room

By reconfiguring your warehouse with drive-in racking systems or drive-through racking, Mechtech can help you increase your storage capacity by 35% or more, without having to expand your facility’s footprint. This allows you to increase your facility’s usable square footage.

These high-density storage solutions are ideal for large quantities of pallets/products warehouses and distribution centers in the grocery and beverage industries.

Optimize Your Facility

The advantage of custom drive-in racking versus selective racks is that a custom-designed drive-in system allows for a greater number of pallets/isles to be stored in the same amount of space, increasing the cubic utilization of your warehouse or facility.

Features such as durable, welded-load arms and rail stops, heavy-duty saddle construction and high-quality powder coat finishes offer additional customization options.

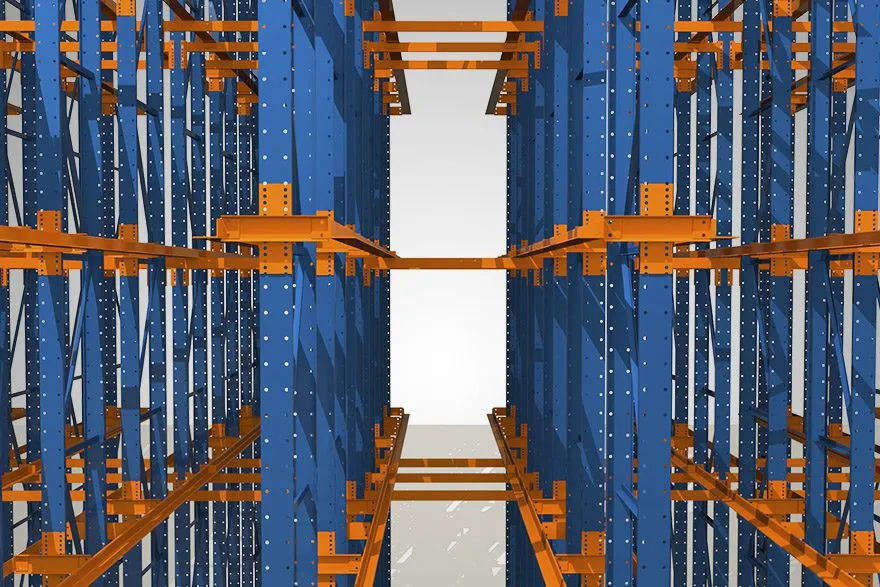

Improve LIFO & FIFO

Mechtech drive-in pallet racks can dramatically reduce your square-foot-to-pallet-position ratio. They are designed for last in, first out (LIFO) storage systems and thus have one end of the rack closed off.

Drive-through pallet racks are open on both ends so forklifts can drive all the way through the system. One side is used for loading pallets and the other for unloading, turning the last in, first out (LIFO) system into a first in, first out (FIFO) system.

Head Office – Amity Building, Maharagama, Srilanka

+94 777 766 763

info@mechtechsolution.com

General Project Process

STEP 1:

Site visit & Evaluation

During the site visit we identify what the objectives are for the project. Our team will arrive in the appropriate gear, get dimensions, thoroughly check the building and review our findings with you, the client.

STEP 2:

Proposal submittal

Utilizing the discoveries collected during the site visit, your assigned sales rep will work with the team to configure a plan that will best serve your needs. We will then submit the project proposal for review.

STEP 3:

Proposal submittal

Once the contract is signed, our team gets to work! We specialize in the design, submittal and approval of Building & High Pile Plans.

STEP 4:

Permit approval & Material delivery

Our team coordinates material delivery to align with permit approval to ensure we are ready to begin installation upon getting permits approved.

STEP 5:

Installation

Our installation team is licensed, bonded and insured. With a Project Manger, an Install Manager and a Head Foreman, on site, we guarantee your project will be properly executed from start to finish.

STEP 6:

Inspection by the city & Client sign off

After installation is complete, we coordinate inspection and final walk through. If all is approved the appropriate department signs off on the project.

KEY INDUSTRIES

WAREHOUSES

DISTRIBUTION

CENTER & 3PLS

LOGISTIC COMPANIES